DIN338 Helslipte HSS M2 Spiralbor

Funksjoner

DIN338 helslipt HSS M2 spiralbor har flere fremragende funksjoner, inkludert:

Høyhastighetsstål (HSS) M2-materiale: Bruken av HSS M2-materiale gir overlegen hardhet, slitestyrke og varmebestandighet, noe som gjør disse borekronene egnet for boring i en rekke materialer, inkludert rustfritt stål, legert stål og ikke-metalliske materialer.

HELSLIPTE FLØTTER OG SKJÆREKANTER: Borekronen er presisjonsslipt for å gi skarpe og konsistente spor og skjærekanter, noe som resulterer i forbedret sponavgang, redusert friksjon og økt borenøyaktighet.

135-graders delt punkt: Borekronen har en 135-graders delt punktdesign, noe som bidrar til å redusere behovet for pilothull, forbedrer sentrerings- og selvsentreringsevnen, og forbedrer boreeffektiviteten.

GLANSENDE OVERFLATE: Den blanke overflaten på borekronen motstår korrosjon, fremmer sponflyt og gir forbedret sikt under drift, noe som bidrar til å forbedre ytelse og levetid.

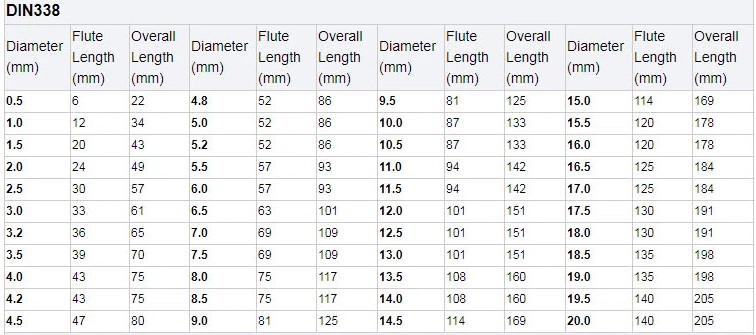

DIN338-kompatibel: Borer overholder DIN338-standardene, noe som sikrer konsistente dimensjoner, produksjon av høy kvalitet og oppfyller bransjestandarder for nøyaktighet og pålitelighet.

Allsidige bruksområder: Disse spiralborene er egnet for generelle boreoppgaver i en rekke materialer, noe som gjør dem allsidige og praktiske for en rekke boreapplikasjoner.

Lang levetid for verktøyet: Kombinasjonen av høykvalitets HSS M2-materialer, presisjonssliping og slitesterkt design bidrar til å forlenge verktøyets levetid og redusere hyppigheten av utskifting og vedlikehold.

Sammen gjør disse funksjonene DIN338 helslipt HSS M2 spiralbor til et pålitelig verktøy med høy ytelse for profesjonelle og industrielle boreapplikasjoner.

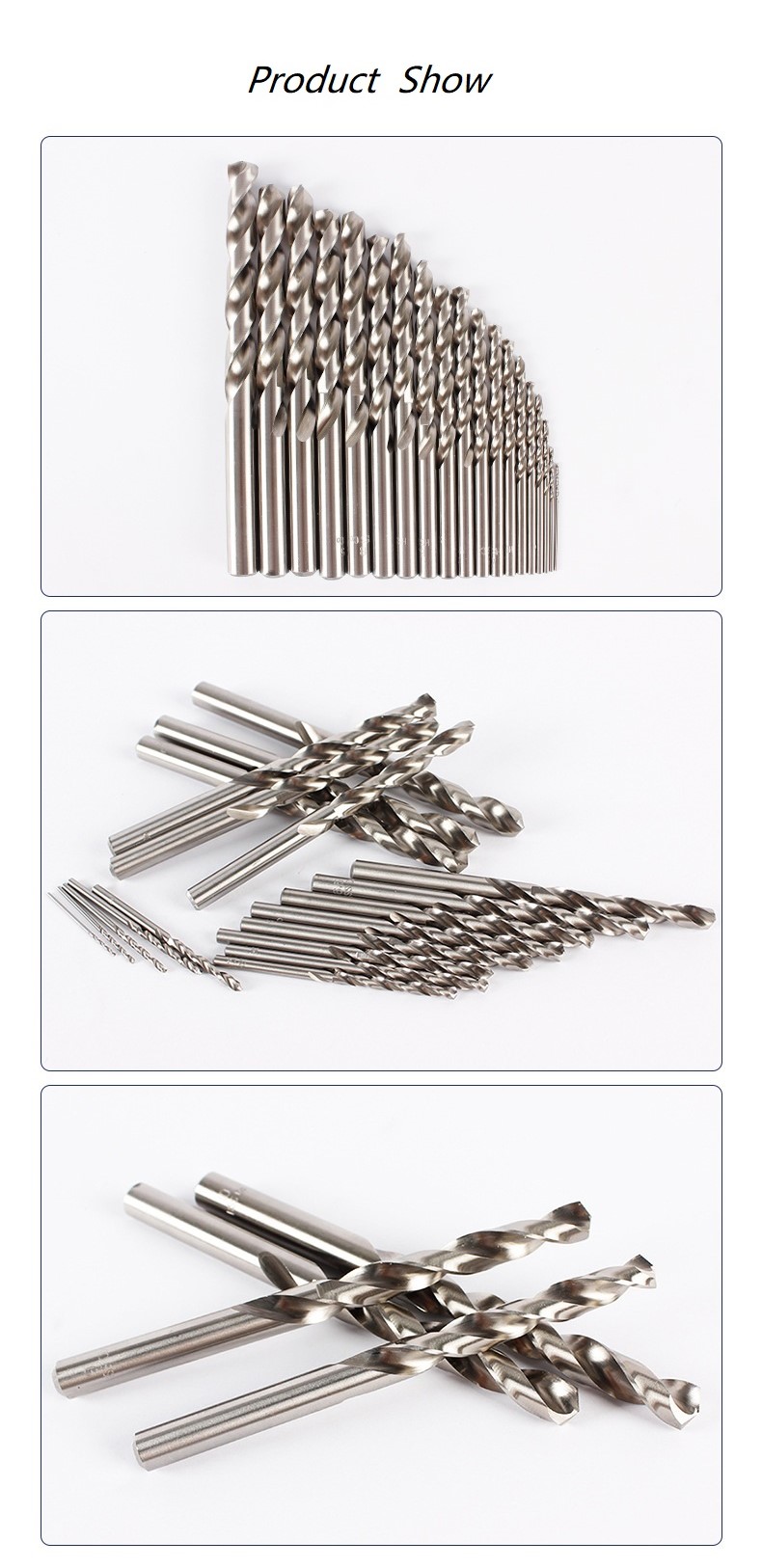

PRODUKT-show

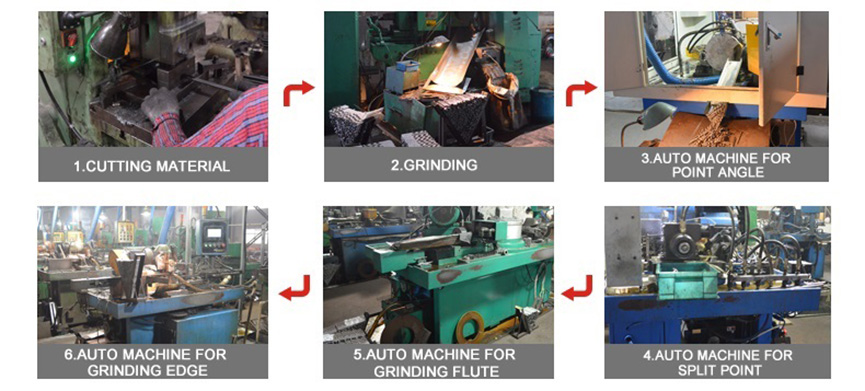

PROSESSFLYT

Fordeler

DIN338 helslipte HSS M2 spiralbor tilbyr en rekke fordeler, inkludert:

Høy holdbarhet: HSS M2-materiale gir overlegen hardhet og slitestyrke for langvarig holdbarhet, spesielt ved boring gjennom tøffe materialer som rustfritt stål, legert stål og ikke-jernholdige metaller.

Presisjon og nøyaktighet: Fullt slipte riller og skjærekanter sikrer presis og jevn boreytelse, og produserer rene og nøyaktige hull.

Effektiv sponavgang: Presisjonsslipte spor og skjærekanter muliggjør effektiv sponavgang, minimerer tilstopping og øker boreeffektiviteten.

Økt borehastighet: 135-graders deltpunktsdesign minimerer behovet for forboring, noe som gir raskere boring og økt produktivitet.

REDUSERER VARME OG FRIKSJON: Høyhastighetsstål og presisjonssliping bidrar til å redusere varmeoppbygging og friksjon under boring, noe som resulterer i jevnere drift og lengre levetid for verktøyet.

Korrosjonsbestandighet: Den blanke overflaten på borekronen er korrosjonsbestandig, noe som forlenger borekronens levetid og opprettholder skjæreytelsen. Allsidighet: Disse borekronene er egnet for en rekke boreapplikasjoner, noe som gjør dem allsidige og praktiske for bruk i en rekke materialer og bransjer.

Ved å levere disse fordelene, gir DIN338 helslipt HSS M2 spiralborkrone pålitelighet, effektivitet og lang levetid i boreoperasjoner.

| DIN338 HSS spiralbor | ||||||||

| Diameter (mm) | Fløytelengde (mm) | Total lengde (mm) | Diameter (mm) | Fløytelengde (mm) | Total lengde (mm) | Diameter (mm) | Fløytelengde (mm) | Total lengde (mm) |

| 0,2 | 2,5 | 19,0 | 5.6 | 57,0 | 93,0 | 11.0 | 94,0 | 142,0 |

| 0,3 | 3.0 | 19,0 | 5.7 | 57,0 | 93,0 | 11.1 | 94,0 | 142,0 |

| 0,4 | 5.0 | 20,0 | 5,8 | 57,0 | 93,0 | 11.2 | 94,0 | 142,0 |

| 0,5 | 6.0 | 22,0 | 5,9 | 57,0 | 93,0 | 11.3 | 94,0 | 142,0 |

| 0,6 | 7.0 | 24.0 | 6.0 | 57,0 | 93,0 | 11.4 | 94,0 | 142,0 |

| 0,7 | 9.0 | 28,0 | 6.1 | 63,0 | 101.0 | 11,5 | 94,0 | 142,0 |

| 0,8 | 10.0 | 30,0 | 6.2 | 63,0 | 101.0 | 11.6 | 94,0 | 142,0 |

| 0,9 | 11.0 | 32,0 | 6.3 | 63,0 | 101.0 | 11.7 | 94,0 | 142,0 |

| 1.0 | 12.0 | 34,0 | 6.4 | 63,0 | 101.0 | 11.8 | 94,0 | 142,0 |

| 1.1 | 14.0 | 36,0 | 6,5 | 63,0 | 101.0 | 11.9 | 101.0 | 151,0 |

| 1.2 | 16,0 | 38,0 | 6.6 | 63,0 | 101.0 | 12.0 | 101.0 | 151,0 |

| 1.3 | 16,0 | 38,0 | 6.7 | 63,0 | 101.0 | 12.1 | 101.0 | 151,0 |

| 1.4 | 18,0 | 40,0 | 6,8 | 69,0 | 109,0 | 12.2 | 101.0 | 151,0 |

| 1,5 | 18,0 | 40,0 | 6,9 | 69,0 | 109,0 | 12.3 | 101.0 | 151,0 |

| 1.6 | 20,0 | 43,0 | 7.0 | 69,0 | 109,0 | 12.4 | 101.0 | 151,0 |

| 1.7 | 20,0 | 43,0 | 7.1 | 69,0 | 109,0 | 12,5 | 101.0 | 151,0 |

| 1.8 | 22,0 | 46,0 | 7.2 | 69,0 | 109,0 | 12.6 | 101.0 | 151,0 |

| 1.9 | 22,0 | 46,0 | 7.3 | 69,0 | 109,0 | 12,7 | 101.0 | 151,0 |

| 2.0 | 24.0 | 49,0 | 7.4 | 69,0 | 109,0 | 12,8 | 101.0 | 151,0 |

| 2.1 | 24.0 | 49,0 | 7,5 | 69,0 | 109,0 | 12,9 | 101.0 | 151,0 |

| 2.2 | 27,0 | 53,0 | 7.6 | 75,0 | 117,0 | 13.0 | 101.0 | 151,0 |

| 2.3 | 27,0 | 53,0 | 7,7 | 75,0 | 117,0 | 13.1 | 101.0 | 151,0 |

| 2.4 | 30,0 | 57,0 | 7,8 | 75,0 | 117,0 | 13.2 | 101.0 | 151,0 |

| 2,5 | 30,0 | 57,0 | 7,9 | 75,0 | 117,0 | 13.3 | 108,0 | 160,0 |

| 2.6 | 30,0 | 57,0 | 8.0 | 75,0 | 117,0 | 13.4 | 108,0 | 160,0 |

| 2.7 | 33,0 | 61,0 | 8.1 | 75,0 | 117,0 | 13,5 | 108,0 | 160,0 |

| 2,8 | 33,0 | 61,0 | 8.2 | 75,0 | 117,0 | 13.6 | 108,0 | 160,0 |

| 2,9 | 33,0 | 61,0 | 8.3 | 75,0 | 117,0 | 13,7 | 108,0 | 160,0 |

| 3.0 | 33,0 | 61,0 | 8.4 | 75,0 | 117,0 | 13,8 | 108,0 | 160,0 |

| 3.1 | 36,0 | 65,0 | 8,5 | 75,0 | 117,0 | 13,9 | 108,0 | 160,0 |

| 3.2 | 36,0 | 65,0 | 8.6 | 81,0 | 125,0 | 14.0 | 108,0 | 160,0 |

| 3.3 | 36,0 | 65,0 | 8,7 | 81,0 | 125,0 | 14.3 | 114,0 | 169,0 |

| 3.4 | 39,0 | 70,0 | 8,8 | 81,0 | 125,0 | 14,5 | 114,0 | 169,0 |

| 3,5 | 39,0 | 70,0 | 8,9 | 81,0 | 125,0 | 14,8 | 114,0 | 169,0 |

| 3.6 | 39,0 | 70,0 | 9.0 | 81,0 | 125,0 | 15,0 | 114,0 | 169,0 |

| 3.7 | 39,0 | 70,0 | 9.1 | 81,0 | 125,0 | 15.3 | 120,0 | 178,0 |

| 3,8 | 43,0 | 75,0 | 9.2 | 81,0 | 125,0 | 15,5 | 120,0 | 178,0 |

| 3.9 | 43,0 | 75,0 | 9.3 | 81,0 | 125,0 | 15,8 | 120,0 | 178,0 |

| 4.0 | 43,0 | 75,0 | 9.4 | 81,0 | 125,0 | 16,0 | 120,0 | 178,0 |

| 4.1 | 43,0 | 75,0 | 9,5 | 81,0 | 125,0 | 16.3 | 125,0 | 184,0 |

| 4.2 | 43,0 | 75,0 | 9.6 | 87,0 | 133,0 | 16,5 | 125,0 | 184,0 |

| 4.3 | 47,0 | 80,0 | 9,7 | 87,0 | 133,0 | 16,8 | 125,0 | 184,0 |

| 4.4 | 47,0 | 80,0 | 9,8 | 87,0 | 133,0 | 17,0 | 125,0 | 184,0 |

| 4,5 | 47,0 | 80,0 | 9,9 | 87,0 | 133,0 | 17.3 | 130,0 | 191,0 |

| 4.6 | 47,0 | 80,0 | 10.0 | 87,0 | 133,0 | 17,5 | 130,0 | 191,0 |

| 4.7 | 47,0 | 80,0 | 10.1 | 87,0 | 133,0 | 17,8 | 130,0 | 191,0 |

| 4.8 | 52,0 | 86,0 | 10.2 | 87,0 | 133,0 | 18,0 | 130,0 | 191,0 |

| 4.9 | 52,0 | 86,0 | 10.3 | 87,0 | 133,0 | 18,5 | 135,0 | 198,0 |

| 5.0 | 52,0 | 86,0 | 10.4 | 87,0 | 133,0 | 18,8 | 135,0 | 198,0 |

| 5.1 | 52,0 | 86,0 | 10,5 | 87,0 | 133,0 | 19,0 | 135,0 | 198,0 |

| 5.2 | 52,0 | 86,0 | 10.6 | 87,0 | 133,0 | 19.3 | 140,0 | 205,0 |

| 5.3 | 52,0 | 86,0 | 10.7 | 94,0 | 142,0 | 19,5 | 140,0 | 205,0 |

| 5.4 | 57,0 | 93,0 | 10.8 | 94,0 | 142,0 | 19,8 | 140,0 | 205,0 |

| 5,5 | 57,0 | 93,0 | 10.9 | 94,0 | 142,0 | 20,0 | 140,0 | 205,0 |